Metal Works

Van Gorkom Yacht Design has been designing metal marine structures for over twenty years. Our extensive mechanical and structural engineering portfolio includes everything from detailed super yacht construction, to an aluminum run-a-boat modeled in 3D, to highly loaded chainplate systems. Please contact us for an elegant yet simple approach to all your engineering needs.

- New Harbor 28 – outboard bracket

- Corsair 31 – mast repair

- IMX 40 – grab bar & instrument support

- Aqua Survey – aluminum structures

- H2 – complete aluminum structural design & 3D modeling

- Fish Eagle – structural modifications

- Molokai Straits 65, 72 and 79 – steel & aluminum structures

- MITseaAH, a 156ft Motor Sailer – aluminum structures

- The Ladd 125 Performance Cruiser – aluminum structures

- Courageous, modern 12 meter – aluminum deck structures & HS chainplates

- Gleam, a classic 12 meter – bronze mast step structure

- Deerfoot 62 – solid aluminum tiller arm

- Tanton 29 Runabout – complete aluminum design & 3D modeling

- McCurdy & Rhodes 46 – redesign of house & cockpit, 3D modeling

- Jutson Mount Gay 30 – fixed aluminum prod design

- Victory ’83, 12 meter – aluminum structures

- Mama Kitty, 42ft Sportsfish – steel shipping cradle

- Blue Marlin, 1937 12 meter – bronze mast and boom fitting

- KZ3 Grand Prix 12 meter – replacement chainplate foundations

- J133 cruiser/racer – stabilization of keel grid

New Harbor Boats, LLC have hired Van Gorkom Yacht Design as their naval architect and structural engineer. Their debut into the powerboat market, the New Harbor 28, was born from the Wasque 26 molds and features a stylish integrated hull extension. VGYD engineered the aluminum out board bracket bolted into the hull extension. This bracket is subject to significant dynamic loads from the 300hp outboard. See New Harbor Boats, LLC for more details.

New Harbor Boats, LLC have hired Van Gorkom Yacht Design as their naval architect and structural engineer. Their debut into the powerboat market, the New Harbor 28, was born from the Wasque 26 molds and features a stylish integrated hull extension. VGYD engineered the aluminum out board bracket bolted into the hull extension. This bracket is subject to significant dynamic loads from the 300hp outboard. See New Harbor Boats, LLC for more details.

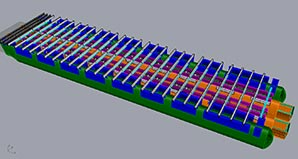

This handsome 33.5 meter aluminum power catamaran, designed by Marples Marine and built by Catman Cats, has been conceived for both luxury cruising and long-range expeditions to remote areas of the world including ice bound regions. VGYD was engaged early on in the project to engineer the structures, model all the structural elements of the yacht, and produce construction details. All scantlings, materials and weldment have been sized to comply with the American Bureau of Shipping’s (ABS) ‘Motor Pleasure Yachts’ design guidelines. As featured in Professional Boatbuilder – An Aluminum Expedition Catamaran – Professional BoatBuilder Magazine (proboat.com).

This handsome 33.5 meter aluminum power catamaran, designed by Marples Marine and built by Catman Cats, has been conceived for both luxury cruising and long-range expeditions to remote areas of the world including ice bound regions. VGYD was engaged early on in the project to engineer the structures, model all the structural elements of the yacht, and produce construction details. All scantlings, materials and weldment have been sized to comply with the American Bureau of Shipping’s (ABS) ‘Motor Pleasure Yachts’ design guidelines. As featured in Professional Boatbuilder – An Aluminum Expedition Catamaran – Professional BoatBuilder Magazine (proboat.com).

JUST LAUNCHED: Van Gorkom Yacht Design (@vgyachtdesign) • Instagram photos and videos

When the aluminum mast of this Corsair 31 suffered some damage in the boat yard where it was being stored, the owner turned to VGYD to inspect and comment on the damage, and then to engineer and detail a repair. Basically, an aluminum plate was modelled, cut and formed to the shape of the existing spar. It was then glued and riveted onto the mast in way of the damage. The original spreader brackets were then attached. The boat is now back on the water and the owner is enjoying the summer coastal sailing in New England.

When the aluminum mast of this Corsair 31 suffered some damage in the boat yard where it was being stored, the owner turned to VGYD to inspect and comment on the damage, and then to engineer and detail a repair. Basically, an aluminum plate was modelled, cut and formed to the shape of the existing spar. It was then glued and riveted onto the mast in way of the damage. The original spreader brackets were then attached. The boat is now back on the water and the owner is enjoying the summer coastal sailing in New England.

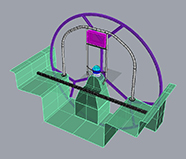

In 2018 this owner purchased an IMX 40 with the goal of competing in the Newport Bermuda Race. Considering the type of racing this boat was going to do, a lot of thought was given to the layout of the cockpit and what might be done to improve the ergonomics. One such measure was to add a grab bar just forward of the wheel. VGYD consulted on the design and engineered a tubular stainless steel arrangement that not only created a strong and stable hand hold but also protected the binnacle from the mainsheet as well as incorporating a mounting support for a B&G screen. The fabrication of the grab bar was done by Custom Stainless Steel in Illinois.

In 2018 this owner purchased an IMX 40 with the goal of competing in the Newport Bermuda Race. Considering the type of racing this boat was going to do, a lot of thought was given to the layout of the cockpit and what might be done to improve the ergonomics. One such measure was to add a grab bar just forward of the wheel. VGYD consulted on the design and engineered a tubular stainless steel arrangement that not only created a strong and stable hand hold but also protected the binnacle from the mainsheet as well as incorporating a mounting support for a B&G screen. The fabrication of the grab bar was done by Custom Stainless Steel in Illinois.

VGYD was asked to consult on the structural design of several self-powered work rigs for Aqua Survey, LLC in New Jersey. The consultation included an analysis of the aluminum structures and recommendations for the longitudinal stiffening and transverse bracing of the existing fleet of vessels. Guidelines were also supplied for the construction of future rigs.

VGYD was asked to consult on the structural design of several self-powered work rigs for Aqua Survey, LLC in New Jersey. The consultation included an analysis of the aluminum structures and recommendations for the longitudinal stiffening and transverse bracing of the existing fleet of vessels. Guidelines were also supplied for the construction of future rigs.

When the Coast Guard revised the average passenger weight criteria, owners of small passenger-carrying vessels operating under the Code of Federal Regulations Sub-Chapter T requirements where faced with a third less paying passengers. The owner of Fisheagle Wild Life Tours in South Carolina contacted Van Gorkom Yacht Design to inquire if it was possible to modify his pontoon boat so as to recoup his passenger count. VGYD performed a study and determined that it was possible by adding an extra set of pontoons and thus increasing the stability of the vessel. VGYD engineered the new structure and ran a complete stability analysis (see Performance Analysis), both of which were approved by the US Coast Guard’s Marine Safety Center.

When the Coast Guard revised the average passenger weight criteria, owners of small passenger-carrying vessels operating under the Code of Federal Regulations Sub-Chapter T requirements where faced with a third less paying passengers. The owner of Fisheagle Wild Life Tours in South Carolina contacted Van Gorkom Yacht Design to inquire if it was possible to modify his pontoon boat so as to recoup his passenger count. VGYD performed a study and determined that it was possible by adding an extra set of pontoons and thus increasing the stability of the vessel. VGYD engineered the new structure and ran a complete stability analysis (see Performance Analysis), both of which were approved by the US Coast Guard’s Marine Safety Center.

These trawler styled motor yachts have been designed for blue-water voyaging by Sponberg Yacht Design. VGYD was hired to assist in the engineering and detailing of the steel hulls and aluminum super structures. The structures were designed for ABS approval. The MS 65 was built by Custom Steel Boats of North Carolina, and the MS75 was built by St. Augustine Marine in Florida (click here for more information). VGYD have recently completed the structures for the MS 79 with construction due to begin some time in 2008.

These trawler styled motor yachts have been designed for blue-water voyaging by Sponberg Yacht Design. VGYD was hired to assist in the engineering and detailing of the steel hulls and aluminum super structures. The structures were designed for ABS approval. The MS 65 was built by Custom Steel Boats of North Carolina, and the MS75 was built by St. Augustine Marine in Florida (click here for more information). VGYD have recently completed the structures for the MS 79 with construction due to begin some time in 2008.

Designed by Lebowitz & Pritchard and Pedrick Yacht Design, this 156ft aluminum motor sailer is one of the most technologically advanced super yachts afloat today. VGYD was contracted by the Pedrick office to help in the engineering of the complicated and highly loaded structure of this yacht. The scantlings were engineered to ABS and MCA standards and confirmed with a detailed finite element analysis. MITseaAH was built at the Pendennis Shipyard in England. (click here for more information)

Designed by Lebowitz & Pritchard and Pedrick Yacht Design, this 156ft aluminum motor sailer is one of the most technologically advanced super yachts afloat today. VGYD was contracted by the Pedrick office to help in the engineering of the complicated and highly loaded structure of this yacht. The scantlings were engineered to ABS and MCA standards and confirmed with a detailed finite element analysis. MITseaAH was built at the Pendennis Shipyard in England. (click here for more information)

In order to engineer the strongest and lightest yacht possible for blue-water cruising, Rob Ladd Yacht Design looked to Van Gorkom Yacht Design for their expertise in engineering innovative structural systems in aluminum that could complement and enhance the clean, sleek lines of the Ladd 125. The entire scantling system for this yacht was designed for ABS approval.

In order to engineer the strongest and lightest yacht possible for blue-water cruising, Rob Ladd Yacht Design looked to Van Gorkom Yacht Design for their expertise in engineering innovative structural systems in aluminum that could complement and enhance the clean, sleek lines of the Ladd 125. The entire scantling system for this yacht was designed for ABS approval.

Pedrick Yacht Design, under the direction of Newport’s Museum of Yachting, were commissioned to help restore Courageous back to her original glory. In turn, PYD called on VGYD to assist in the structural engineering and design of such areas as the high-strength stainless steel chainplate fittings and the aluminum deck structures that supports them. The chainplates were fabricated by CAM Machine Corp.

Pedrick Yacht Design, under the direction of Newport’s Museum of Yachting, were commissioned to help restore Courageous back to her original glory. In turn, PYD called on VGYD to assist in the structural engineering and design of such areas as the high-strength stainless steel chainplate fittings and the aluminum deck structures that supports them. The chainplates were fabricated by CAM Machine Corp.

Built in 1937, this classic wooden 12 meter is one of the jewels of the Newport yachting scene. When the boat started to exhibit some sagging problems, Perrotti Performance Design was engaged to find a solution. PPD turned VGYD to assist in the engineering and design of a new bronze maststep support grid system to help stiffen the existing wooden structure. The fabrication was done by CAM Machine Corp. and installation by Newport Yacht Joinery.

Built in 1937, this classic wooden 12 meter is one of the jewels of the Newport yachting scene. When the boat started to exhibit some sagging problems, Perrotti Performance Design was engaged to find a solution. PPD turned VGYD to assist in the engineering and design of a new bronze maststep support grid system to help stiffen the existing wooden structure. The fabrication was done by CAM Machine Corp. and installation by Newport Yacht Joinery.

Unable to find any off-the-shelf components for his auto-pilot, the owner of this Deerfoot 62 had VGYD design and engineer a new tiller arm. A thorough analysis of the loads was conducted and a 3D model was created, which was used to mill the part from a solid aluminum billet. This has been a long term project for this owner who acquired a fiberglass hull several years ago and has been building and outfitting the boat as a world class cruising yacht. Van Gorkom Yacht Design was also contracted to design the keel and rudder for the boat.

Unable to find any off-the-shelf components for his auto-pilot, the owner of this Deerfoot 62 had VGYD design and engineer a new tiller arm. A thorough analysis of the loads was conducted and a 3D model was created, which was used to mill the part from a solid aluminum billet. This has been a long term project for this owner who acquired a fiberglass hull several years ago and has been building and outfitting the boat as a world class cruising yacht. Van Gorkom Yacht Design was also contracted to design the keel and rudder for the boat.

Yves Tanton sought out the engineering services of VGYD for the complete structural design & 3D modeling of his 29 foot aluminum runabout. All the metal work was modeled as developable surfaces for easy plate cutting making the construction process economical and relatively quick to build.

Yves Tanton sought out the engineering services of VGYD for the complete structural design & 3D modeling of his 29 foot aluminum runabout. All the metal work was modeled as developable surfaces for easy plate cutting making the construction process economical and relatively quick to build.

This beautiful 1976 aluminum racing sloop is receiving a new lease on life with a total refit of the boat. VGYD was commissioned to redesign and engineer the rig, rudder, a new deck hardware arrangement, and a completely new cabin house & cockpit geometries. The new aluminum structure was modeled entirely in 3D allowing most of the individual plates to be pre-cut before construction. The refit is being done by Island Boatworks in Louisiana.

This beautiful 1976 aluminum racing sloop is receiving a new lease on life with a total refit of the boat. VGYD was commissioned to redesign and engineer the rig, rudder, a new deck hardware arrangement, and a completely new cabin house & cockpit geometries. The new aluminum structure was modeled entirely in 3D allowing most of the individual plates to be pre-cut before construction. The refit is being done by Island Boatworks in Louisiana.

In preparing his boat for the Bermuda 1-2, the owner of this Scott designed boat contacted VGYD to help him optimize the sailing configuration for the best rating possible. Part of that optimization was the design and implementation of a fixed aluminum prod, which greatly simplified the process of setting a kite as well being rating friendly.

In preparing his boat for the Bermuda 1-2, the owner of this Scott designed boat contacted VGYD to help him optimize the sailing configuration for the best rating possible. Part of that optimization was the design and implementation of a fixed aluminum prod, which greatly simplified the process of setting a kite as well being rating friendly.

Van Gorkom Yacht Design was retained by Jim Gretzky of Sail Spars Design Inc. to assist in what was an extensive refit of the aluminum 12 meter Victory ’83 (K22). VGYD wias involved in the engineering of several critically loaded structural components such as the chainplates, mast ram foundation and the primary deck and cockpit structure, as well as on-site project management. Update: Her first race since the completion of the refit and Victory ’83 places second in the “Modern” division of the 2008 12m Nationals.

Van Gorkom Yacht Design was retained by Jim Gretzky of Sail Spars Design Inc. to assist in what was an extensive refit of the aluminum 12 meter Victory ’83 (K22). VGYD wias involved in the engineering of several critically loaded structural components such as the chainplates, mast ram foundation and the primary deck and cockpit structure, as well as on-site project management. Update: Her first race since the completion of the refit and Victory ’83 places second in the “Modern” division of the 2008 12m Nationals.

When this group of anglers purchased a sportsfish with the idea of taking it to Africa to go deep sea fishing, they contacted VGYD to engineer a shipping cradle that could be mounted on a container pallet on the deck of a cargo ship. Once in South Africa, the cradle then had to be disassembled and transport by road to Tanzania where the boat was to be based. The entire structure, except for the hull pads, was fabricated in steel.

When this group of anglers purchased a sportsfish with the idea of taking it to Africa to go deep sea fishing, they contacted VGYD to engineer a shipping cradle that could be mounted on a container pallet on the deck of a cargo ship. Once in South Africa, the cradle then had to be disassembled and transport by road to Tanzania where the boat was to be based. The entire structure, except for the hull pads, was fabricated in steel.

This beautiful classic yacht was built for Sopwith by Camper and Nicholson in 1937. For the passed five years the boat has been undergoing a complete refurbishment in Finland under the watchful eye of Pedrick Yacht Designs. VGYD played a significant role in the engineering of many aspects of the refit including the design of most of the mast and boom fittings which were fabricated in bronze. The boat was re-launched this year (2014) in the Baltic.

This beautiful classic yacht was built for Sopwith by Camper and Nicholson in 1937. For the passed five years the boat has been undergoing a complete refurbishment in Finland under the watchful eye of Pedrick Yacht Designs. VGYD played a significant role in the engineering of many aspects of the refit including the design of most of the mast and boom fittings which were fabricated in bronze. The boat was re-launched this year (2014) in the Baltic.

After almost 30 years of hard use the pin holes in the aluminum chainplate foundations in KZ3, a Granf Prix 12 meter, were found to be showing signs of fatigue. Contracting through Pedrick Yacht Designs, VGYD helped engineer a solution by designing a replacement section for the foundation plate.

After almost 30 years of hard use the pin holes in the aluminum chainplate foundations in KZ3, a Granf Prix 12 meter, were found to be showing signs of fatigue. Contracting through Pedrick Yacht Designs, VGYD helped engineer a solution by designing a replacement section for the foundation plate.

When the after keel bolts and the keel grid support system of this cruiser/racer were found to be structurally unstable, McMichaels Boat Yard in Mamroneck NY contacted VGYD to analysis the problem and come up with an appropriate solution. A stainless steel box was devised which was potted and bolted into the keel grid, effectively locking in the keel bolts and the hull structure.

When the after keel bolts and the keel grid support system of this cruiser/racer were found to be structurally unstable, McMichaels Boat Yard in Mamroneck NY contacted VGYD to analysis the problem and come up with an appropriate solution. A stainless steel box was devised which was potted and bolted into the keel grid, effectively locking in the keel bolts and the hull structure.